Thermal Engineering Experts

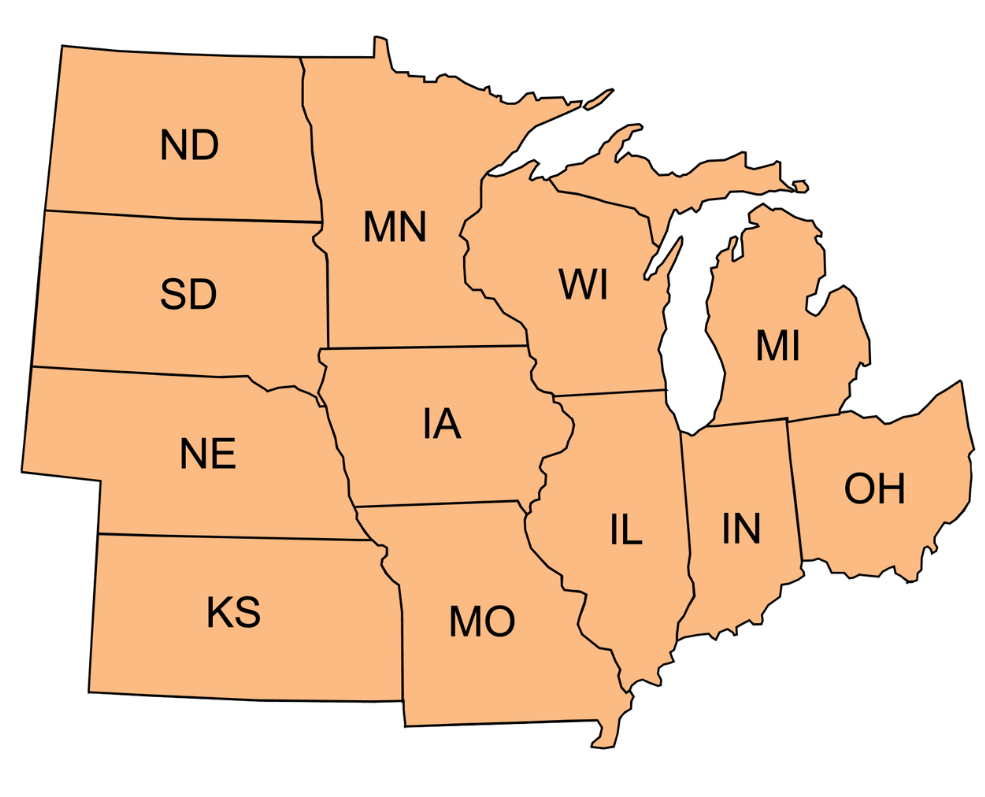

Midwest Heat Exchanger Systems for Industrial & Manufacturing Applications

Heavy-Duty Heat Exchanger Fabrication for Manufacturing & Process-Driven Industries

Industries We Serve Across the Midwest

Asphalt Production

Asphalt plants across the Midwest need rugged, efficient thermal equipment to support heavy aggregate drying and precise bitumen heating in varied weather conditions. Our custom shell and tube exchangers deliver reliable, high-temperature performance that keeps production running smoothly.

Food & Beverage

With major meat packing, dairy, grain, and beverage facilities, the Midwest requires rugged, sanitary thermal solutions. Our stainless-steel exchangers support accurate temperature control and high-capacity food processing environments across the region.

HVAC & Building Infrastructure

Hospitals, educational facilities, and commercial buildings throughout the Midwest rely on robust HVAC equipment to handle wide swings in seasonal temperatures. Our custom heat exchangers and tube bundle replacements ensure dependable, long-term thermal performance in essential building systems.

Manufacturing & Industrial

The Midwest’s manufacturing and industrial plants—from metals and machinery to plastics and large-scale processing—need heavy-duty thermal solutions. Our custom heat exchangers handle high pressures, varied process fluids, and the rigorous, around-the-clock demands of Midwest production environments.

Marine & Offshore

While not an offshore region, many Midwest facilities supporting marine equipment manufacturing or inland waterway systems still require corrosion-resistant thermal solutions. Our copper-nickel and specialty-alloy exchangers provide durability for marine-related applications along major rivers and industrial ports.

Oil & Gas Industries

The Midwest’s energy sector, from fuel blending to transmission and storage facilities, requires rugged thermal equipment capable of handling demanding process loads. Our custom heat exchangers are designed for durability, pressure tolerance, and consistent performance across varied operating conditions.

Pharmaceuticals & Biotechnology

Pharmaceutical plants and biotechnology facilities throughout the Midwest depend on sanitary thermal systems to maintain strict production conditions. Our stainless-steel heat exchangers provide precise temperature control and robust reliability for highly regulated, process-critical applications.

Petrochemical & Chemical Processing

Chemical plants and processing operations across the Midwest rely on durable thermal equipment to handle aggressive media, high pressures, and demanding production cycles. Our engineered heat exchangers and tube bundle replacements offer dependable performance in corrosive and process-intensive environments.

Power Generation & Utilities

Power generation sites across the Midwest require rugged heat transfer equipment to support heavy workloads, fluctuating seasonal temperatures, and process-driven operations. Our high-efficiency exchangers are built for durability, stable cooling, and continuous high-demand service.

Core Industrial Heat Exchanger Products & Capabilities for the Midwest

Custom Shell & Tube Heat Exchangers

Tube Bundle Replacements

Specialized Industrial Fabrication

Material Flexibility for Harsh Conditions

Compliance & Engineering Standards

KAM Thermal Equipment, Ltd

Experts in thermal design, engineering and manufacturing since 1906

- 4th gen, family owned for over a century

- ASME Section VIII, Division 1

- TEMA compliant

- Proudly made in USA serving worldwide

Why Choose KAM Thermal

Manufacturing and industrial plants across the Midwest count on our equipment for rugged performance in heavy-duty, process-driven operations. We provide:

- Efficient turnaround for custom exchangers and bundle replacements

- Precision designs for high-pressure, high-load industrial applications

- Exact matching of legacy, worn, or undocumented bundles

- Material expertise suited for high temperatures, corrosive media, and seasonal climate swings

- A proven lineage of American engineering excellence

Midwest facilities rely on our durable fabrication and dependable thermal performance to keep production moving.

Case Study: Boosting Asphalt Production with a Custom Heat Exchanger Retrofit

A major asphalt producer needed a thermal performance upgrade to support modern

polymerized asphalt requirements. Their older heat exchanger struggled to reach

efficient operating temperatures, limiting throughput and slowing daily production.

KAM Thermal engineered a custom shell and tube heat exchanger designed to match:

- Existing saddle spacing

- Fixed piping layout

- Required thermal duty

- Plant footprint with no structural changes

The upgrade was developed through precise remote collaboration, using exchanged

measurements, drawings, and thermal modeling to ensure a perfect fit without

expensive redesign work.

Results & Performance Improvements

The upgraded exchanger increased output temperature by approximately 60°F, allowing the plant to reach nearly 380°F during polymerization and eliminating previous production bottlenecks.

- Two additional full batches produced per day

- Improved process startup and thermal efficiency

- No changes required to foundations, saddles, or piping

- Seamless integration into the existing system layout

These enhancements delivered higher throughput, better temperature stability, and a more profitable production cycle without major plant downtime.

start your project now

Contact us today

Working hours

Mon-Fri, 8am to 4pm EST

Custom Solutions

Shell & Tube Heat Exchangers

Reach out to KAM Thermal Equipment for durable heat exchanger manufacturing and accurate tube bundle replacements backed by over a century of U.S. industrial craftsmanship. Midwest plants rely on our fast turnaround, proven engineering, and consistent support.