KAM Thermal Equipment

Wisconsin Custom Heat Exchangers

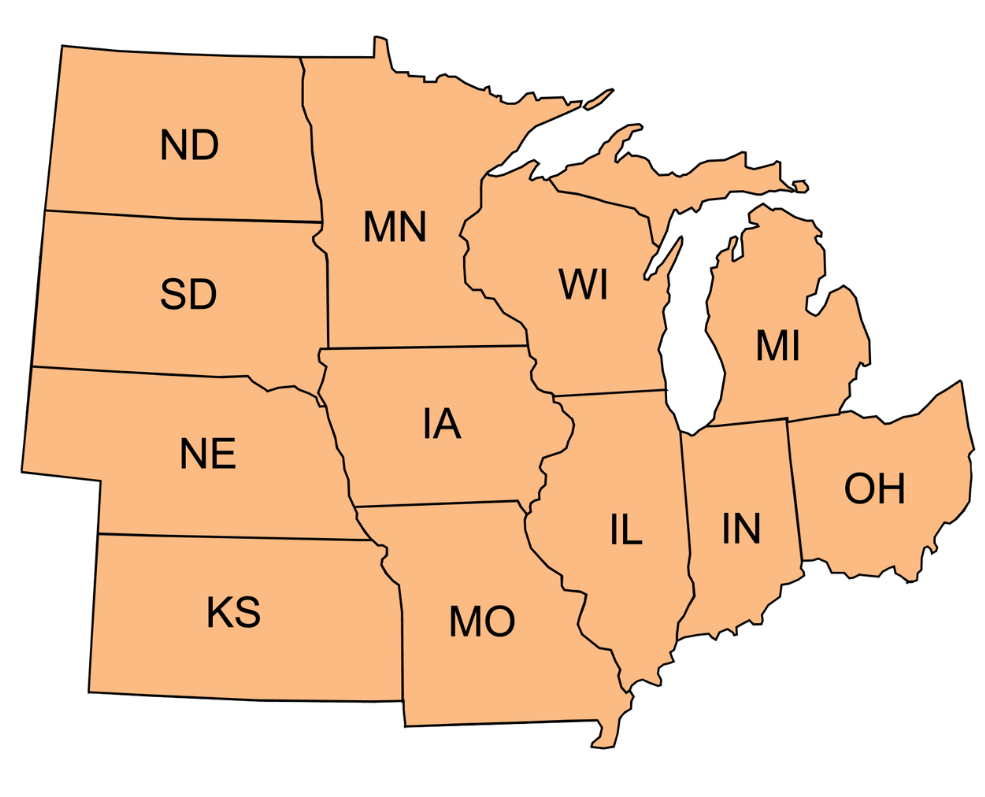

Specialized Heat Exchanger Fabrication – WI

Asphalt Production

Wisconsin asphalt facilities require reliable heating equipment capable of handling cold-weather swings and heavy loads. KAM Thermal supplies exchangers engineered for both durability and performance.

Food & Beverage

Wisconsin’s dairy and food processors need sanitary, corrosion-resistant heat exchangers. KAM Thermal provides stainless-steel units engineered for stable, high-volume production.

HVAC & Building Infrastructure

Wisconsin buildings—from hospitals to commercial campuses—require dependable HVAC thermal equipment. KAM Thermal provides long-lasting exchangers and tube bundles designed for high-demand environments.

Manufacturing & Industrial

Wisconsin manufacturers rely on efficient thermal equipment for metals, dairy processing, food production, and machinery. KAM Thermal provides exchangers built for demanding industrial cycles.

Marine & Offshore

Wisconsin Great Lakes operations require corrosion-resistant exchangers designed for freshwater marine conditions. KAM Thermal provides copper-nickel units built for continuous marine service.

Power Generation & Utilities

Wisconsin power facilities depend on durable thermal equipment to support cooling and turbine requirements throughout seasonal extremes. KAM Thermal supplies exchangers built for long-term service.

Pharmaceuticals & Biotechnology

Wisconsin’s medical, biotech, and research facilities depend on clean, corrosion-resistant thermal systems. KAM Thermal provides sanitary-grade exchangers built for precise control.

Petrochemical & Chemical Processing

Wisconsin specialty chemical, coatings, and materials processors require corrosion-resistant thermal systems. KAM Thermal supplies exchangers designed for reliable, high-performance duty.

Core Products & Capabilities in the South Central Region

Custom Shell & Tube Heat Exchangers

Tube Bundle Replacements

Specialized Industrial Fabrication

Material Flexibility for Harsh Conditions

Compliance & Engineering Standards

KAM Thermal Equipment, Ltd

Experts in thermal design, engineering and manufacturing since 1906

- 4th gen, family owned for over a century

- ASME Section VIII, Division 1

- TEMA compliant

- Proudly made in USA serving worldwide

Why Choose KAM Thermal

Industrial teams across Wisconsin rely on KAM Thermal Equipment because we provide:

- Quick production of custom exchangers and tube bundles

- Thermal engineering built for high-load, continuous-duty environments

- Reliable duplication of obsolete or unmarked bundles

- Material options designed for corrosion and elevated temperatures

- A century of dependable American craftsmanship

Wisconsin facilities depend on our equipment to maintain process stability.

start your project now

Contact us today

Working hours

Mon-Fri, 8am to 4pm EST